EXCELLENCE DRIVEN BY EXPERIENCE

World’s Leading Industry

Years of Experience

Intro

Sakthi Top

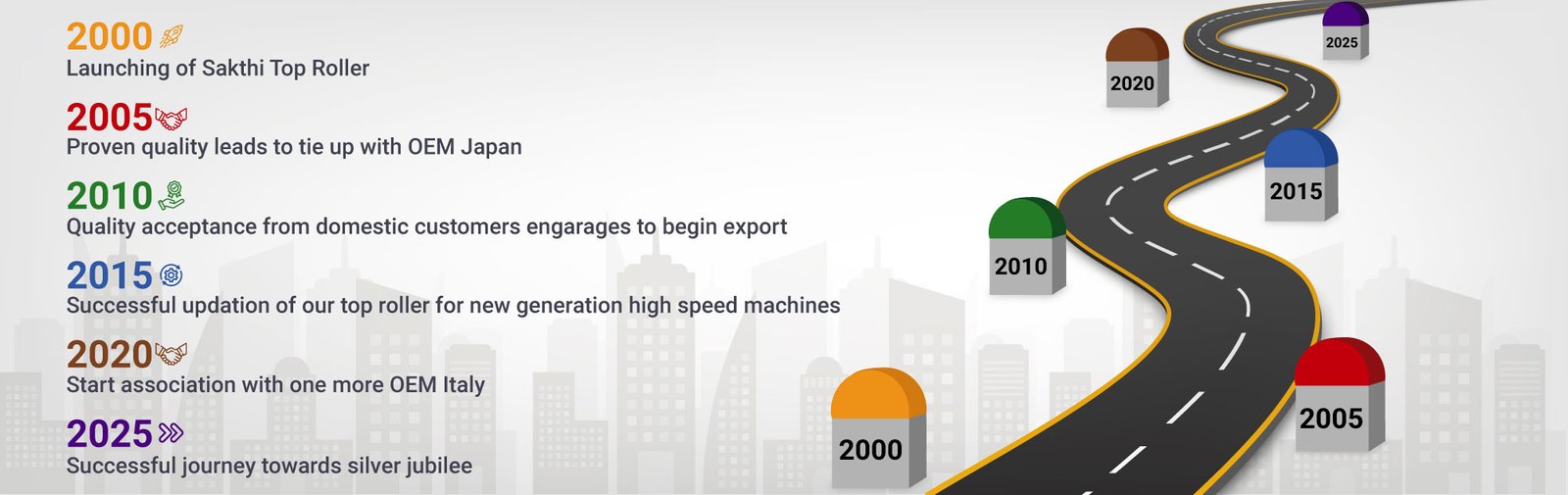

SAKTHI started during the year 2000 and it is promoted and run by a team of dedicated qualified engineers decade of manufacturing and development experience in Engineering based Spinning Industry. SAKTHI’s motto is to provide quality products in the Spinning process and make the customers to achieve optimum level of production and quality.

Rigorous Quality Control

‘Sakthi’ Top roller quality is taken care in every stage of operations up to final assy by QC team. As per customer

choice any make and kind of cots can be duly mounted and supplied with our top roller.

Synthetic Rubber Cots

Indigenous Cots

Overseas Cots

German, Switzerland, Japan Make Twin layer can be supplied with Sakthi Top roller duly mounted.

Mounting and Buffing

Top Roller and End Bush

Bearing and Grease

Top Roller and End Bush

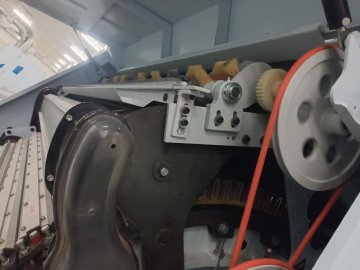

New generation top roller and End bush are gaining popularity in various textile sectors worldwide. In such a scenario, the design and development of these top rollers are very crucial. One of the most challenging parts is the selection of materials for different machines. Our main focus in top roller and end bush various engineering materials are used for the development . The challenging part in the design and development of a top rollers and end bush is its material selection which plays a crucial role.

Bearings

Grease

Shells & End Bushes

Technical Expertise Matters

Our Products